NanoSet Color is a technologically advanced liquid concrete dye that adds gorgeous color to the concrete substrate. The concentrated formula is a proprietary blend of dye solutions, not pigment dispersions, that penetrate deeply to create a durable, fast-drying color with exceptional lightfastness.

The eco friendly product formula may be diluted with the NanoSet Densifier NS, water or acetone to create a translucent finish for a variety of concrete surfaces (e.g. broom finish, troweled, etc.). Seal with compatible sealers.

While NanoSet Color may be used as a penetrating colorant for a variety of porous substrates, it is commonly used in conjunction with the NanoSet™ Polishing System or other polishing systems. See instructions below and read the technical data sheet for more info.

Packaging

Available in 8 oz. or 32 oz. units that are respectively mixed into 1 gallon or 5 gallons of NanoSet Densifier NS, water, or a 1:1 water/acetone mixture.

Features & Benefits

- Excellent dye lightfastness (For Interior Use Only)

- True dye color solution; not a pigment dispersion

- Liquid concentrate dissolves in less than minutes when compared to hours for powder dyes

- Concentrated dye colors can be diluted up to 16:1 or as needed to achieve desired intensity

- Dries very fast and is flash point compliant

- Ultra low viscosity stain has no HAPs or TAPs

- Concrete dye colors are eco-friendly, comply with all VOC regulations and are UV stable, especially when sealed with NanoSet Protector

- Very easy to apply with standard equipment

- Packaged in concentrate for cost-effective shipping and storage

- Use as an alternative to “acid stain” or as an aid to fix troubled acid stain projects

- Provides vibrant color to polished concrete floor surface without any film build-up

- Proprietary concrete dye formula includes penetrating aid to help infiltrate the concrete surface deeply

- Includes UV blockers to improve resistance to UV damage

- Color formula is concentrated to minimize shipping costs; safe to ship by air

- Concrete dye colors are compatible and may be blended to create custom-specific colors

Important Downloads

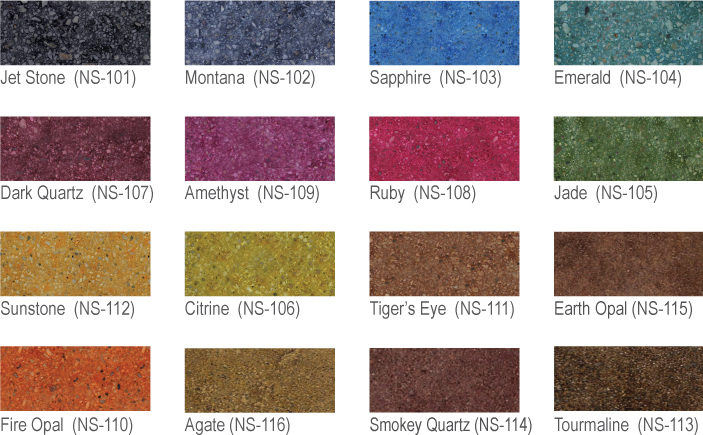

Color Chart

Colors are approximate and, as close as possible, represent dyed concrete with a flat-troweled or polished finish. NewLook cannot control (and is not responsible for) application methods, slab color, or other job site condition and, therefore, cannot guarantee the final appearance or an exact color match. Actual color results may vary.

Advanced Water-Based

Liquid Concrete Dye Concentrate

Not Private-Labeled.

Manufactured by NewLook.

© 2013 NewLook International, Inc. All Rights Reserved

Follow Us:

Instructions for Polishing Concrete Floors with NanoSet Color (See Tech Data Sheet for More Info):

NanoSet Color liquid concrete dye may be used to color any concrete floor surface, including polished concrete floors. To maximize penetration and color performance, the polished concrete floor must be a CSP of 1 or 2 on the International Concrete Repair Institute (ICRI) Concrete Surface Profile (CSP) chart. Visit www.ICRI.org for more information. NewLook recommends representative job site samples prior to installation on project.

- Concrete surface pH of 7 – 9 is recommended for optimal results. Test pH with a pH pencil.

- NanoSet Color is best applied to polished concrete floors with a professional hand pump sprayer that is acetone-resistant (if needed). Apply with a micro-fiber pad, brush or other tools as needed.

- Dilute NanoSet Color depending upon the desired color intensity. Recommended dilution is up to 16 parts with either water, ready-to-use (diluted) NanoSet Densifier NS, or a 50/50 acetone/water blend.

- Protect adjacent surfaces from over-spray. Assure any taped or stenciled surfaces are well adhered as to avoid NanoSet Color bleed. Stains are permanent.

- Assure surface to be colored is clean from debris, oils, or other contaminants that may disrupt penetration. Surface must be clean and dry prior to installation. Damp surfaces will reduce color penetration.

- Color introduction may vary based on desired look, surface specifications and equipment usage. Apply NanoSet Color concrete dye during the polishing process after 400-grit resin level and above then allow it to dry. Wipe away any excess dye or use an auto-scrubber with a white pad and water. Test for excess residual color by wiping a dry white cloth across the colored surface. Some residual color wiping is acceptable, however, significant residue will require additional cleaning until excess is removed.

- Dry times will vary based on carrier used, surface, temperature and humidity. Dry time may reach up to 45-60 minutes when diluted with water only.

- Color intensity or loss may vary due to a variety of factors. In some cases, NanoSet Color concrete dye may be introduced more than once to improve color intensity at 800 or 1500 –grit. The concrete dye color must dry before following up with subsequent resin grit grinding.

- Dry concrete polishing is recommended, as wet concrete polishing may remove color during the process.

- Use multiple dye colors for enhanced faux effects. Assure each color is cleaned individually as to avoid contamination of colors to adjacent areas.

- Once the concrete dye color has completely dried, apply NanoSet Protector to help lock in and enhance the color. Follow NanoSet Protector instructions for optimal performance.

Important Tags: how to dye concrete, concrete dye, concrete dye colors, concrete stain, polished concrete floors, concrete coloring, colored concrete

(Orders fulfilled by Distributors)

"NanoSet Color concrete dye colors do exactly what NewLook says they'll do. [They're] easy to use...great color finish...an excellent choice for anyone working with polished concrete floors!"

-- B. Hill; Miami, FL

Concrete Surface Preparation

Beautify & Revitalize

Protect (Sealers) & Maintain

Sundries